X-Ray Inspection: A Powerful Tool For Electronics Quality Control

X-Ray Inspection: A Powerful Tool for Electronics Quality Control

Related Articles: X-Ray Inspection: A Powerful Tool for Electronics Quality Control

Introduction

With great pleasure, we will explore the intriguing topic related to X-Ray Inspection: A Powerful Tool for Electronics Quality Control. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

X-Ray Inspection: A Powerful Tool for Electronics Quality Control

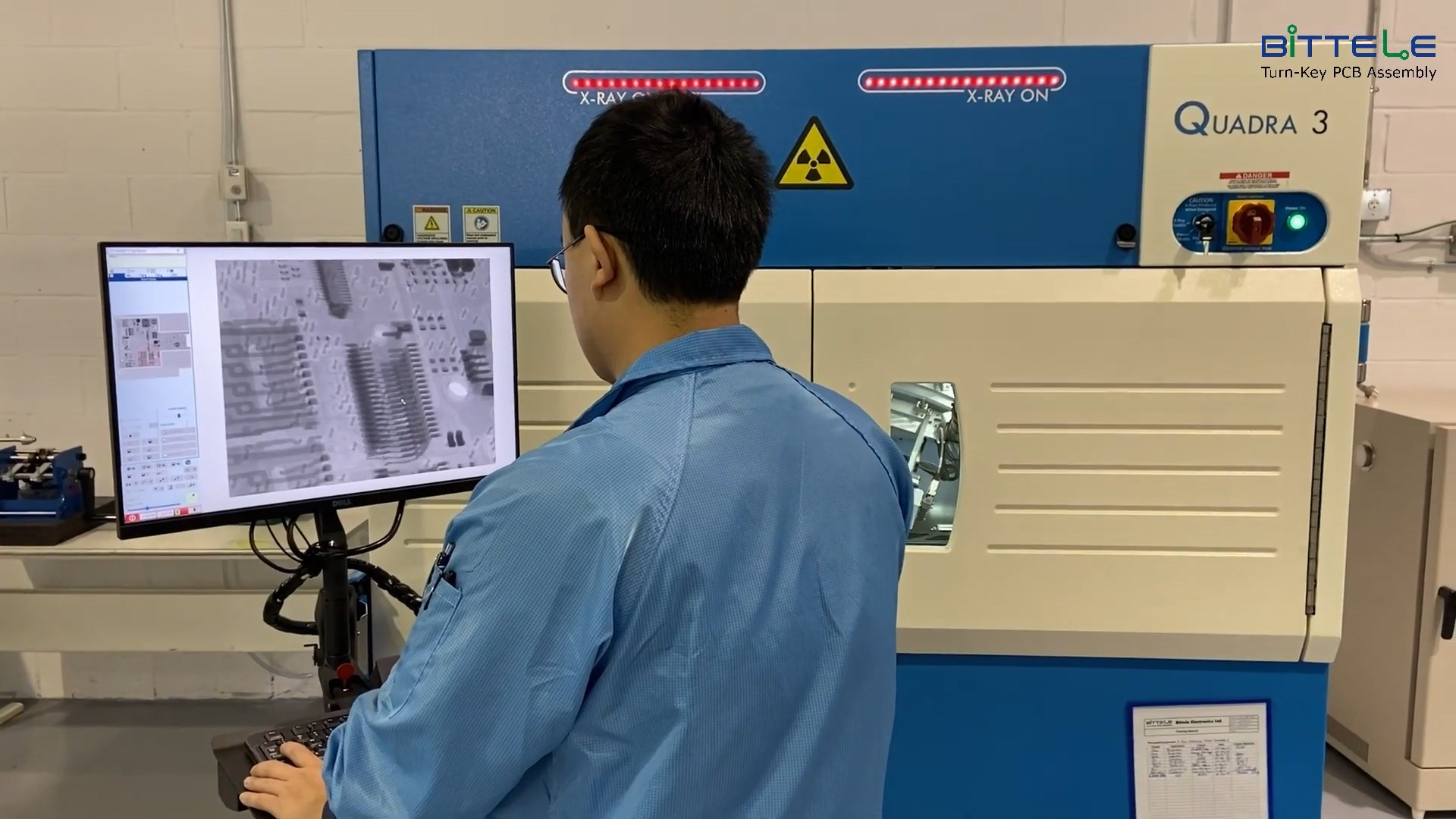

In the intricate world of electronics manufacturing, ensuring product quality and reliability is paramount. One critical tool employed to achieve this is X-ray inspection. This technology, often referred to as X-ray imaging or non-destructive testing (NDT), offers a powerful and versatile method for analyzing the internal structure of electronic components and assemblies.

Understanding the Fundamentals of X-Ray Inspection

X-ray inspection leverages the unique properties of electromagnetic radiation. X-rays, characterized by their high energy and short wavelengths, can penetrate various materials, including metals, plastics, and ceramics. As X-rays pass through a component, they interact with the material’s atoms, causing some to be absorbed and others to be scattered. The resulting pattern of absorption and scattering creates an image that reveals the internal structure of the object.

Benefits of X-Ray Inspection in Electronics Manufacturing

X-ray inspection provides numerous advantages for electronics manufacturers, contributing to:

- Enhanced Quality Control: X-rays expose internal flaws and defects that are invisible to the naked eye. This includes issues such as solder joint defects, component misalignment, voids, cracks, and foreign object contamination. By identifying these issues early in the production process, manufacturers can prevent costly rework and product failures.

- Process Optimization: X-ray inspection data can be used to analyze and improve manufacturing processes. By understanding the root causes of defects, manufacturers can implement corrective actions to minimize their occurrence, leading to improved product consistency and yield.

- Reduced Production Costs: Early detection of defects through X-ray inspection helps minimize scrap and rework, reducing overall production costs.

- Enhanced Product Reliability: By ensuring the integrity of internal components, X-ray inspection contributes to the creation of more reliable and durable electronic products.

- Increased Customer Satisfaction: Delivering high-quality products with fewer defects leads to increased customer satisfaction and brand loyalty.

Types of X-Ray Inspection Systems for Electronics

The specific X-ray inspection system chosen depends on the application and the size and complexity of the electronic components being inspected. Here are some common types:

- 2D X-Ray Systems: These systems produce a two-dimensional image, similar to a photograph, revealing the internal structure of the object. 2D X-ray systems are widely used for inspecting printed circuit boards (PCBs), integrated circuits (ICs), and other small electronic components.

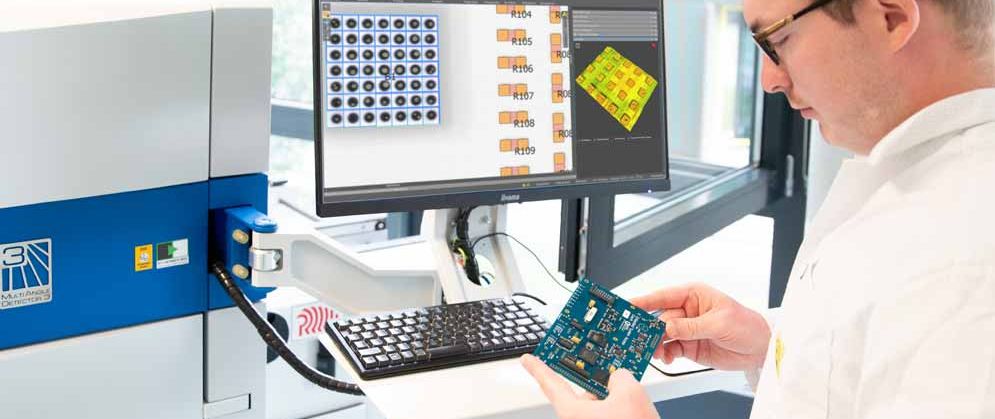

- 3D X-Ray Systems: These systems utilize advanced algorithms and imaging techniques to create a three-dimensional representation of the object. 3D X-ray systems provide greater depth perception and allow for detailed analysis of complex geometries, making them suitable for inspecting larger assemblies and complex electronic devices.

- Computed Tomography (CT) Scanners: CT scanners are a specialized type of 3D X-ray system that generates detailed cross-sectional images of the object. CT scans offer exceptional resolution and allow for the precise visualization of internal features, making them ideal for inspecting high-density components and intricate assemblies.

Applications of X-Ray Inspection in Electronics

X-ray inspection plays a crucial role in various aspects of electronics manufacturing, including:

- Component Inspection: X-ray inspection is widely used to verify the quality of individual components, such as ICs, transistors, capacitors, and resistors. This ensures that these components meet the required specifications and are free from internal defects.

- Solder Joint Inspection: X-ray inspection is an essential tool for inspecting solder joints on PCBs. It reveals hidden defects such as voids, cracks, and insufficient solder fill, which can compromise the electrical connection and lead to product failure.

- Foreign Object Detection (FOD): X-rays can detect foreign objects embedded within electronic components or assemblies. This is particularly important for preventing damage to sensitive components and ensuring product safety.

- Wire Bond Inspection: X-ray inspection can be used to verify the quality of wire bonds, which are crucial for connecting components on PCBs. It helps identify issues such as misaligned bonds, broken wires, and insufficient bonding pressure.

- Assembly Inspection: X-ray inspection is used to assess the overall quality and integrity of electronic assemblies. It helps identify issues such as component misalignment, missing components, and improper wiring.

Key Considerations for Implementing X-Ray Inspection

When implementing X-ray inspection in an electronics manufacturing facility, several factors should be considered:

- Inspection Requirements: The specific inspection requirements, such as the type of defects to be detected and the required resolution, will determine the appropriate X-ray system.

- Throughput: The required inspection throughput, or the number of components inspected per unit time, will influence the choice of system and its automation capabilities.

- Safety: X-ray systems emit ionizing radiation, requiring appropriate safety measures to protect personnel and the environment.

- Cost: The cost of X-ray inspection systems can vary depending on the system’s capabilities and features.

- Training: Proper training is essential for operating and maintaining X-ray systems effectively.

FAQs on X-Ray Inspection for Electronics

Q: Is X-ray inspection a destructive testing method?

A: No, X-ray inspection is a non-destructive testing (NDT) method. It does not damage the components or assemblies being inspected.

Q: What are the safety concerns associated with X-ray inspection?

A: X-ray systems emit ionizing radiation, which can be harmful to humans. Therefore, it is essential to follow appropriate safety protocols, such as using shielding, limiting exposure time, and monitoring radiation levels.

Q: What types of defects can X-ray inspection detect?

A: X-ray inspection can detect a wide range of defects, including solder joint defects, component misalignment, voids, cracks, foreign object contamination, and wire bond issues.

Q: How does X-ray inspection differ from optical inspection?

A: Optical inspection uses visible light to examine the surface of objects. X-ray inspection, on the other hand, uses high-energy electromagnetic radiation to penetrate materials and reveal their internal structure.

Q: What are the advantages of using X-ray inspection over other inspection methods?

A: X-ray inspection offers several advantages over other inspection methods, including its ability to detect hidden defects, its non-destructive nature, and its versatility for inspecting a wide range of materials.

Tips for Optimizing X-Ray Inspection in Electronics Manufacturing

- Define Clear Inspection Requirements: Establish specific inspection requirements based on the types of defects to be detected and the required resolution.

- Select the Appropriate System: Choose an X-ray system that meets the specific inspection requirements and the throughput needs.

- Optimize Image Acquisition: Ensure proper sample preparation, alignment, and image acquisition parameters to obtain high-quality images.

- Implement Automated Inspection: Consider automating the inspection process to improve efficiency and reduce human error.

- Develop Robust Defect Classification Algorithms: Use advanced algorithms to automatically identify and classify defects in X-ray images.

- Implement Continuous Improvement: Regularly review inspection data and implement process improvements to enhance quality and reduce defects.

Conclusion

X-ray inspection is a vital tool for ensuring the quality and reliability of electronic products. By providing detailed insights into the internal structure of components and assemblies, X-ray inspection helps manufacturers identify and address potential issues before they lead to product failures. By leveraging the capabilities of X-ray inspection, electronics manufacturers can enhance their quality control processes, optimize production efficiency, and deliver high-quality, reliable products to their customers.

Closure

Thus, we hope this article has provided valuable insights into X-Ray Inspection: A Powerful Tool for Electronics Quality Control. We hope you find this article informative and beneficial. See you in our next article!

You may also like

Recent Posts

- The Enduring Appeal Of XP Jewelry: A Timeless Symbol Of Achievement

- A Global Tapestry Of Adornment: Exploring World Collections Of Jewelry

- The Evolution Of A Brand: Understanding The Name Change Of Lola Rose Jewellery

- Navigating The UK’s Jewelry Wholesale Landscape: A Comprehensive Guide

- The Allure Of Effy Jewelry: Unveiling The Reasons Behind Its Premium Pricing

- The Enduring Appeal Of Gold Jewelry: A Timeless Investment

- The Art Of Harmony: Elevating Your Style Through Accessory Coordination

- The Comprehensive Guide To Wholesale Jewelry Supplies Catalogs: A Treasure Trove For Jewelry Makers And Businesses

Leave a Reply