The Power Of Precision: A Comprehensive Guide To Jewelry Adhesive

The Power of Precision: A Comprehensive Guide to Jewelry Adhesive

Related Articles: The Power of Precision: A Comprehensive Guide to Jewelry Adhesive

Introduction

With great pleasure, we will explore the intriguing topic related to The Power of Precision: A Comprehensive Guide to Jewelry Adhesive. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Power of Precision: A Comprehensive Guide to Jewelry Adhesive

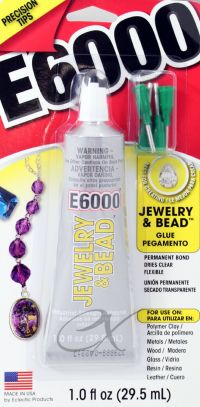

In the realm of jewelry making and repair, precision is paramount. A single misplaced bead or a loose setting can diminish the beauty and integrity of a piece. This is where the power of a specialized adhesive comes into play. Jewelry adhesive, often referred to as "jewelry glue," provides a reliable solution for securely attaching various materials used in jewelry creation, ensuring durability and longevity.

This comprehensive guide delves into the intricacies of jewelry adhesive, exploring its properties, applications, and considerations for successful use.

Understanding the Science Behind Jewelry Adhesive

Jewelry adhesive is not simply a generic glue. It is a meticulously formulated product designed to meet the specific demands of the jewelry industry. The key characteristics that define a high-quality jewelry adhesive include:

- Strong Bond: The adhesive must create a robust bond that can withstand the rigors of daily wear and tear. This means it must be resistant to scratching, abrasion, and even the impact of accidental knocks.

- Clear Finish: The adhesive should be transparent or have a minimal color so it does not detract from the beauty of the jewelry piece.

- Fast Curing Time: A quick curing time allows for efficient work, minimizing the time required for the adhesive to dry and harden.

- Flexibility: Jewelry adhesive should be flexible enough to accommodate the movement and bending of jewelry pieces without cracking or breaking the bond.

- Resistance to Chemicals: The adhesive must be resistant to the chemicals commonly used in jewelry cleaning and care, such as alcohol and solvents.

- Water Resistance: Jewelry adhesive should be water-resistant to prevent the bond from weakening or dissolving when exposed to moisture.

- Non-Toxic and Safe: For the well-being of both the jeweler and the wearer, the adhesive should be non-toxic and safe for use.

Types of Jewelry Adhesive

Jewelry adhesives come in various forms, each tailored to specific applications and materials. The most common types include:

- Epoxy Resin Adhesive: Epoxy resins are two-part adhesives that mix together to create a strong, durable bond. They are particularly well-suited for attaching metal, glass, and gemstones.

- Cyanoacrylate Adhesive (Super Glue): Cyanoacrylate adhesives, often referred to as "super glue," are known for their fast curing time and strong bonds. They are effective for attaching small components and delicate jewelry elements.

- Acrylic Adhesive: Acrylic adhesives are water-based and offer a strong, flexible bond. They are a popular choice for attaching plastics and other non-porous materials.

Choosing the Right Jewelry Adhesive

The choice of jewelry adhesive depends on the specific project and the materials being used. Consider the following factors when selecting the right adhesive:

- Materials Being Bonded: Different adhesives have varying levels of adhesion to different materials. Research the specific adhesive’s compatibility with the materials you are using.

- Strength of Bond Required: The strength of the bond needed will determine the type of adhesive you choose. For high-stress applications, a strong epoxy resin adhesive is ideal. For lighter applications, a super glue or acrylic adhesive might suffice.

- Curing Time: The curing time of the adhesive is an important factor to consider. A quick-curing adhesive is suitable for quick repairs, while a longer-curing adhesive allows for more time to position components precisely.

- Flexibility: If the jewelry piece is expected to bend or move, a flexible adhesive is essential. Acrylic adhesives and some epoxy resins offer excellent flexibility.

- Appearance: The adhesive’s appearance is a consideration, especially for visible areas. Choose a clear or minimally colored adhesive to maintain the jewelry’s aesthetic appeal.

Tips for Successful Jewelry Adhesive Application

Achieving a strong and lasting bond with jewelry adhesive requires careful application. Here are some tips to ensure success:

- Prepare the Surfaces: Before applying the adhesive, thoroughly clean the surfaces to be bonded. Remove any dirt, grease, or residues that could hinder adhesion.

- Apply a Thin Layer: Apply a thin, even layer of adhesive to both surfaces to be bonded. Avoid excessive amounts, as this can lead to a messy finish and weaken the bond.

- Position Carefully: Carefully position the components to be bonded and hold them in place until the adhesive begins to set.

- Clamp or Weight: For larger or heavier components, use clamps or weights to maintain pressure and ensure a secure bond.

- Curing Time: Allow the adhesive to cure completely according to the manufacturer’s instructions. Avoid handling or stressing the jewelry until the curing process is complete.

- Test Adhesion: After the adhesive has cured, gently test the bond to ensure it is strong and secure.

FAQs about Jewelry Adhesive

Q: What is the best jewelry adhesive for metal jewelry?

A: Epoxy resin adhesives are generally considered the best choice for bonding metal jewelry. They provide a strong, durable bond that can withstand the rigors of daily wear.

Q: Can I use super glue for jewelry?

A: Super glue (cyanoacrylate adhesive) can be used for jewelry, but it is not ideal for all applications. It is best suited for small components and delicate jewelry elements. For larger or heavier components, a stronger adhesive like epoxy resin is recommended.

Q: How long does jewelry adhesive take to dry?

A: The drying time for jewelry adhesive varies depending on the type of adhesive and the surrounding temperature and humidity. Check the manufacturer’s instructions for specific drying times.

Q: Can I use jewelry adhesive on gemstones?

A: Yes, jewelry adhesive can be used on gemstones, but it is crucial to choose an adhesive specifically designed for use with gemstones. Some adhesives may react with the gemstone and damage it.

Q: How do I remove jewelry adhesive?

A: Removing jewelry adhesive can be challenging. For some adhesives, a solvent like acetone or nail polish remover can be used. However, always test the solvent on an inconspicuous area first to ensure it does not damage the jewelry.

Conclusion

Jewelry adhesive plays a vital role in the creation and repair of jewelry, providing a reliable solution for securely attaching various materials. By understanding the properties and applications of different types of jewelry adhesive, jewelers and hobbyists can ensure their creations are durable, beautiful, and long-lasting.

Choosing the right adhesive, applying it correctly, and following the manufacturer’s instructions are crucial steps in maximizing the effectiveness of jewelry adhesive. With careful consideration and proper technique, jewelry adhesive can be a powerful tool in the hands of any jewelry enthusiast.

Closure

Thus, we hope this article has provided valuable insights into The Power of Precision: A Comprehensive Guide to Jewelry Adhesive. We appreciate your attention to our article. See you in our next article!

You may also like

Recent Posts

- The Enduring Appeal Of XP Jewelry: A Timeless Symbol Of Achievement

- A Global Tapestry Of Adornment: Exploring World Collections Of Jewelry

- The Evolution Of A Brand: Understanding The Name Change Of Lola Rose Jewellery

- Navigating The UK’s Jewelry Wholesale Landscape: A Comprehensive Guide

- The Allure Of Effy Jewelry: Unveiling The Reasons Behind Its Premium Pricing

- The Enduring Appeal Of Gold Jewelry: A Timeless Investment

- The Art Of Harmony: Elevating Your Style Through Accessory Coordination

- The Comprehensive Guide To Wholesale Jewelry Supplies Catalogs: A Treasure Trove For Jewelry Makers And Businesses

Leave a Reply